such systems are batch-fed versions into which the dung and an appropriate quantity of

water are loaded without being pre-mixed. The feed-stock is usually hauled to and from the

digester in wheelbarrows or baskets.

Chicken droppings

Chicken droppings can only be used if the chickens roost above a suitable dung collecting

area of limited size. Otherwise, the sand or sawdust fraction would be disproportionately

high. Chicken droppings can be fed into plants which are primarily filled with cow dung

without any problem. There is a latent danger of high ammoniac concentration with pure

chicken dung, but despite this there are many well functioning biogas plants combined with

egg or meat producing factories. The collected droppings are hard and dry, so that they have

to be pulverized and mixed with water before they can be loaded into the digester.

Mechanical mixing is advisable. The proportion of methane in biogas from chicken

excrement is up to 60%.

Human excrements

In most cultures, handling human excrement is loaded with taboos. Thus, if night soil is to be

used in a biogas system, the toilets in question should drain directly into the system so that

the night soil is fermented without pretreatment. The amount of water accompanying the

night soil should be minimized by ensuring that no water taps or other external sources drain

into the toilet bowls, and cleaning/flushing should be limited to rinsing out with about 0.5 - 1

liter water from a bowl. Western-style flush tanks should not be used in connection with

small-size biogas plants.

In areas subject to frequent or seasonal water shortages, sand traps are a must, since wiping

with stones is often the only means of cleaning after using the toilet.

The problem of scum

If there is heavy gas release from the inlet but

not enough gas available for use, a thick scum

layer is most likely the reason. Often the gas

pressure does not build up because of the

continuous gas release through the inlet for

weeks. There is a danger of blocking the gas

pipe by rising scum because of daily feeding

without equivalent discharge. The lid (or man-

hole) must be opened or the floating drum

removed and scum is to be taken out by hand.

Separation of material

Straw, grass, stalks and even already dried dung

tends to float to the surface. Solid and mineral

material tends to sink to the bottom and, in the

course of time, may block the outlet pipe or

reduce the active digester volume. In properly

mixed substrate with not too high water contents,

there is no such separation because of sufficient

friction within the paste-like substance.

Substrate

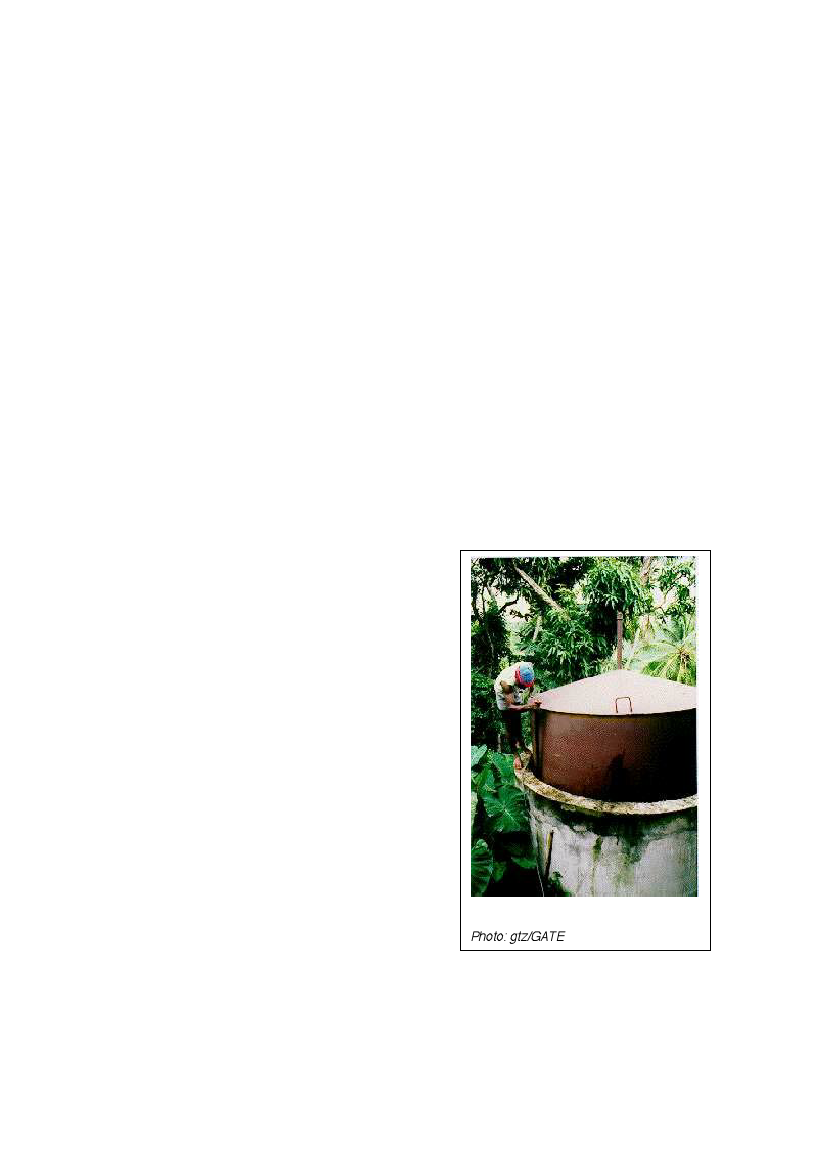

Figure 25: Destruction of the scum in

a floating-drum plant in the Carribean

Photo: gtz/GATE

With pure and fresh cattle dung there is usually no scum problem. Floating layers will

become a problem when e.g. undigestible husks are part of the fodder. This is often the case

in pig feeds. Before installing a biogas plant at a piggery, the kind of fodder and consequently

the kind of dung, must be checked to ensure that it is suitable for a biogas plant. It might be

necessary to grind the fodder into fine powder. The user must be aware of the additional

costs before deciding on a biogas unit. The problem is even bigger with poultry droppings.

The kind of fodder, the sand the chicken pick up, and the feathers falling to the ground make

44